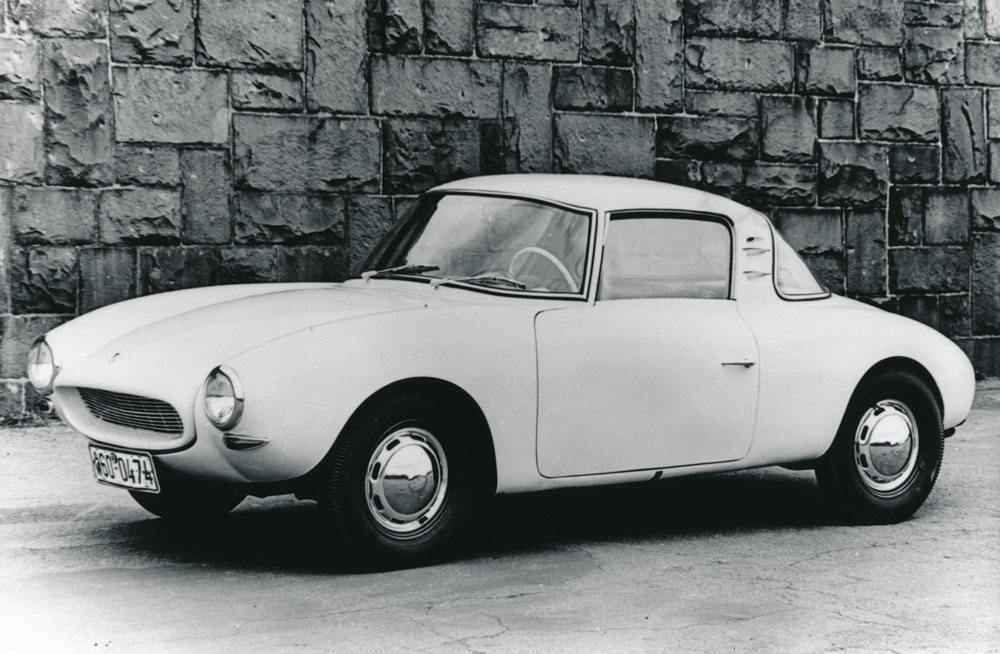

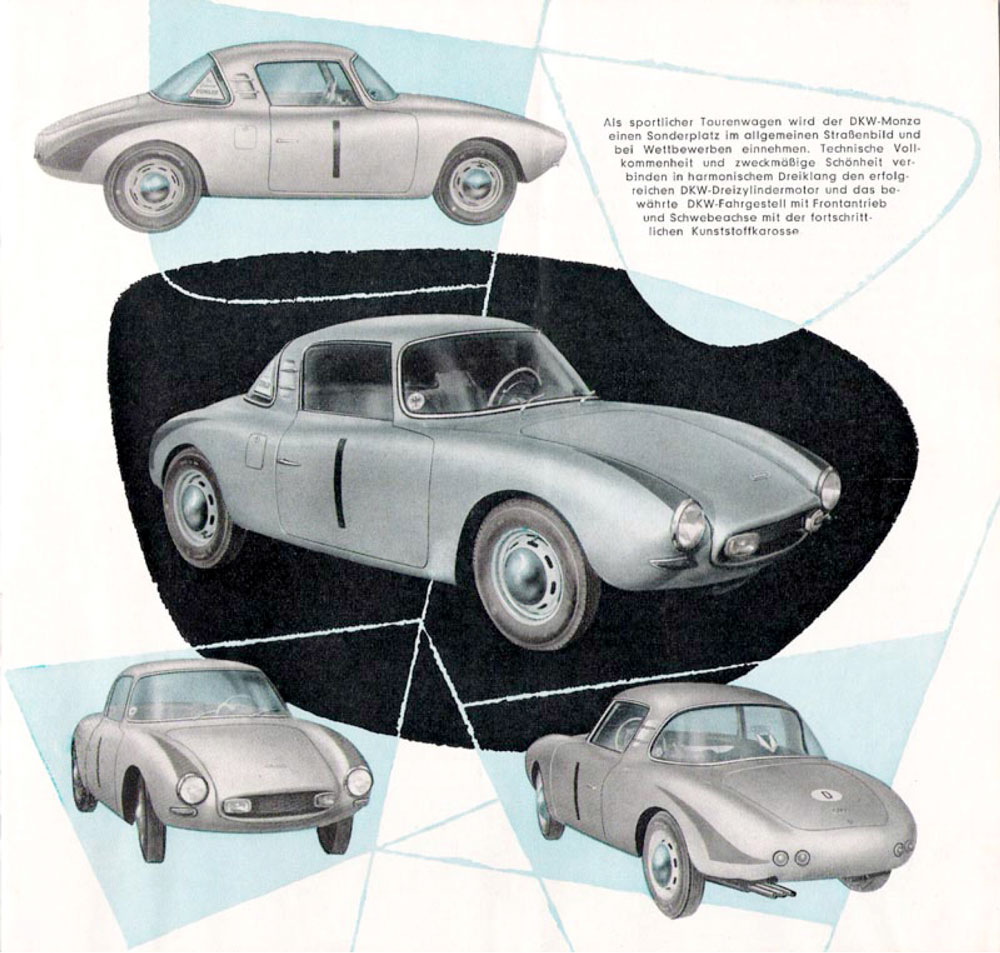

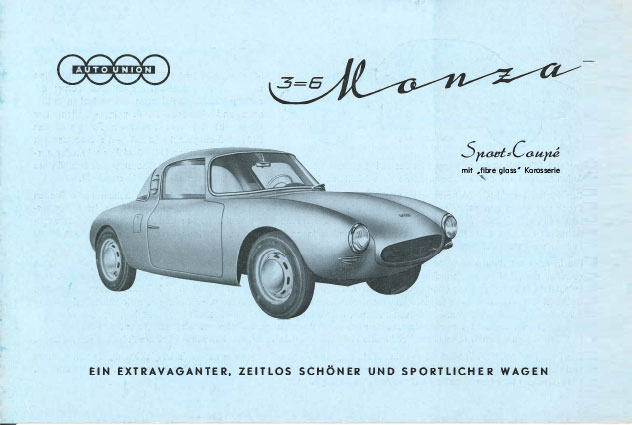

The DKW Monza was based on the slightly modified chassis of the “Grosses DKW3=6” which was unveiled in 1955. The DKW competition drivers Günther Ahrens and A. W. Mantzel ordered the fibre glass body from Dannenhauer and Stauss in Stuttgart. The latter built about 10 cars with this body, the first of which was on the shorter and narrower chassis of the DKW F 91.

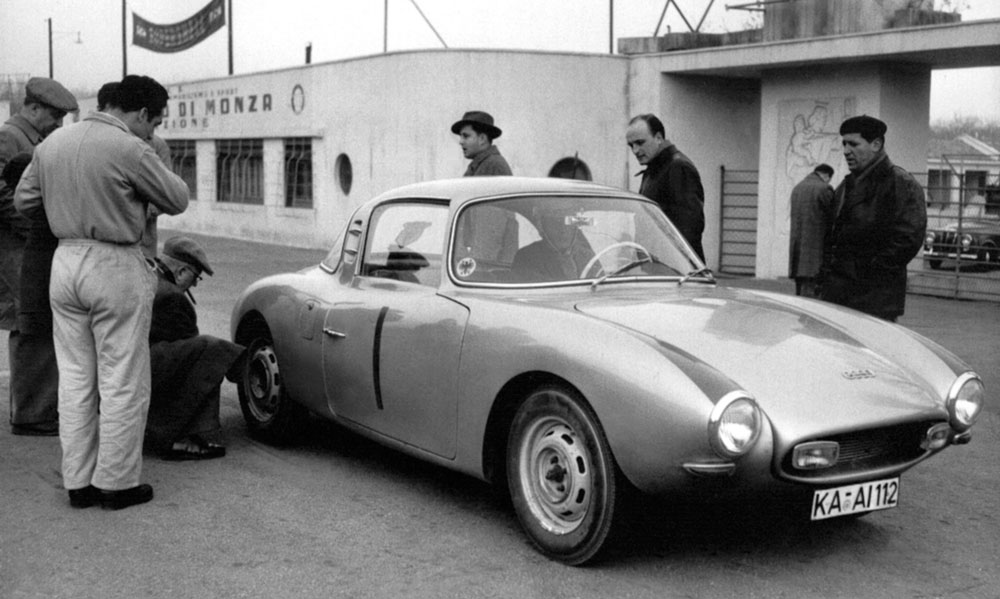

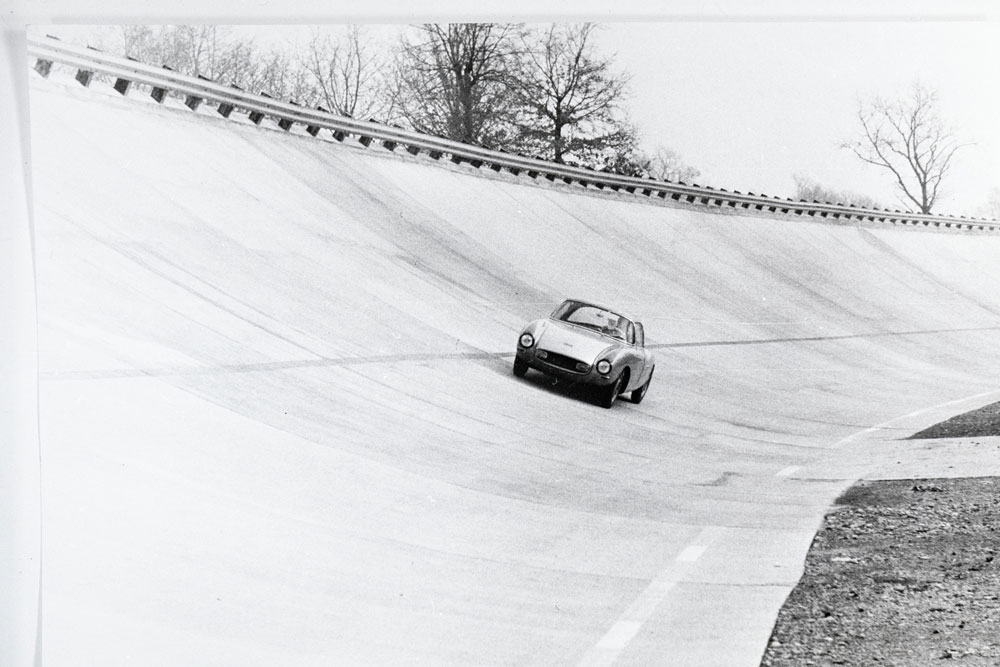

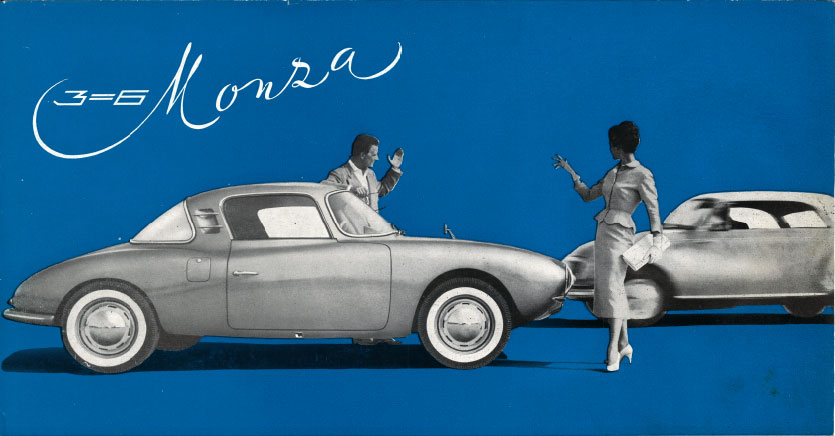

In December 1956 Günther Ahrens, Roberto Barbay, Heinz Meier and Georg Theiler drove the slightly modified fifth production model to beat the 4000 miles, 48 hours, 5000 miles, 10,000 kilometres and 72 hours long distance records for production cars on the Monza track – hence the name of this two-seater coupé. Auto Union bought the record winning car back and sent it on a promotional tour.

The Heidelberg-based DKW dealer Fritz Wenk took charge of the project and arranged for the bodywork to be built by the commercial vehicle body manufacturer Massholder in Heidelberg. After production there came to a standstill several times, all the production facilities were moved once again, this time to Stuttgart.

Robert Schenk Karosseriebau in Stuttgart modified the Monza for volume production and subsequently manufactured the greater part of the total number of Monzas built. The vehicles manufactured by Schenk can be recognised by the smaller bonnet, larger wheel arches and the drop-shaped air vents on the B pillar.

Auto Union commenced volume manufacture of its own sports car, the AU 1000 SP, in 1958. Shortly afterwards the supply contract for chassis for Wenk were terminated. In spite of full order books, the basis for this ambitious project was literally pulled out from under Wenk. A few bodies were built in Stuttgart up to 1960 against specific customer orders, the customers supplying the chassis. The era of the fibre glass body was over.

The exact number of cars manufactured has not survived but it can be said that the maximum number manufactured by the three bodybuilders cannot be more than 230 vehicles.